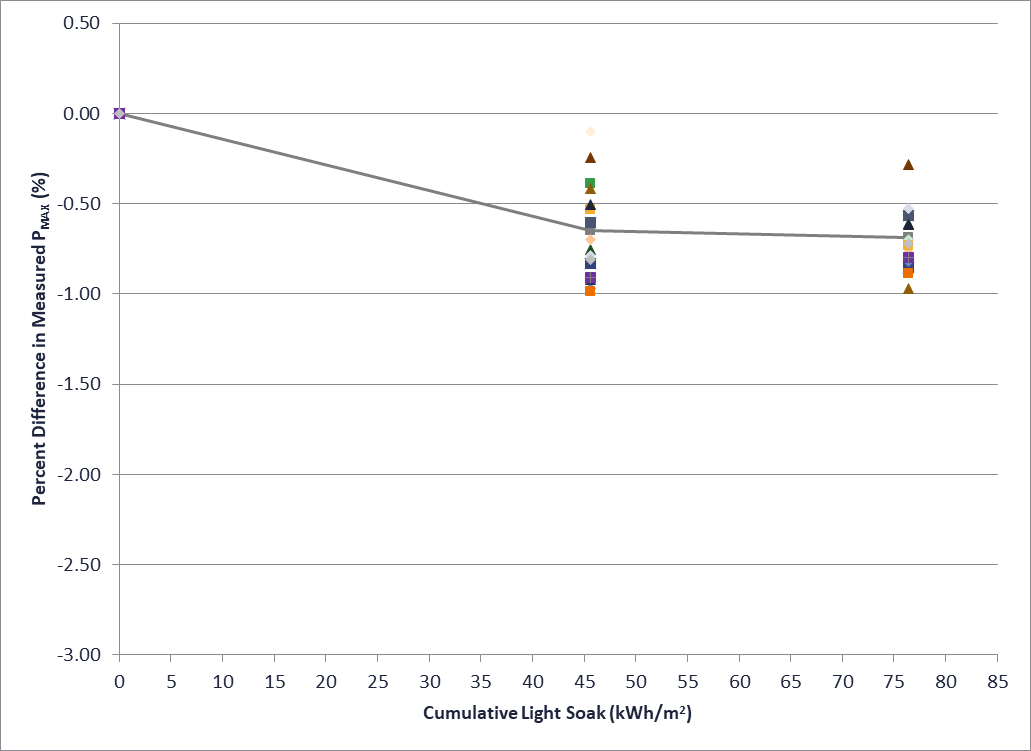

Light-induced degradation (LID) and light-and-elevated temperature-induced degradation (LETID) are cell-based phenomena triggered by light exposure that are often incorporated in energy yield models. LID rates vary by cell technology and typically stabilize within a few days or weeks of field operation. LETID mainly affects PERC cells and may be an unintended consequence of certain LID-reduction techniques applied in manufacturing. LETID is most severe in hot climates.

The most common form of LID occurs when light exposure triggers the formation of boron-oxygen complexes in boron-doped silicon solar cells. The majority of the PERC modules that PVEL has tested for this Scorecard are doped by gallium, which has significantly mitigated LID from historical levels.

LETID can affect advanced cell types, such as PERC. It occurs when cells reach temperatures over 40°C during operation. These operating temperatures occur in hot environments and in temperate regions during periods of high irradiance on hot days. Degradation from LETID reaches its maximum point after months or years. After several more years, some of this power loss may eventually recover.